A recent study conducted by scientists from the Institute of Science and Technology for Energy and Environment (ISTEE), under the Vietnam Academy of Science and Technology (VAST), has successfully developed a high-performance forward osmosis (FO) membrane capable of removing heavy metals from electroplating wastewater. This achievement represents an important advance in the application of environmentally friendly membrane technology to address industrial water pollution in Vietnam.

The electroplating industry, a key sector in mechanical manufacturing, electronics, and automotive production, has become a significant source of water pollution. Wastewater from electroplating contains large concentrations of toxic heavy metals such as arsenic, lead, and nickel, along with chemicals including cyanide and sulfate. Only a small portion of these pollutants are effectively treated, while most are discharged into the environment, posing long-term risks to human health and ecosystems.

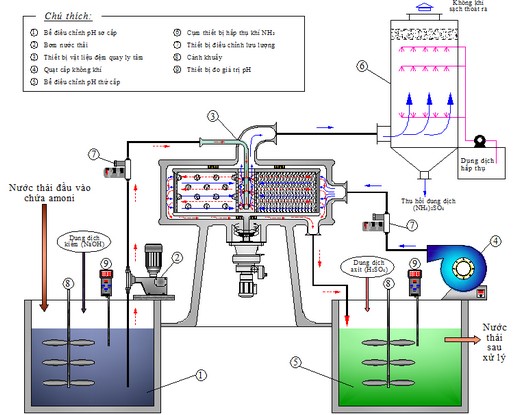

Traditional treatment technologies—such as chemical precipitation, ion exchange, adsorption, or nanofiltration—face challenges including high operational costs, sludge generation, and reduced performance under complex wastewater conditions. In contrast, forward osmosis (FO) has emerged as a promising solution thanks to its low energy consumption, reduced membrane fouling, and strong capability in heavy metal removal. However, one of the main limitations of FO is its low water flux, primarily due to internal concentration polarization (ICP).

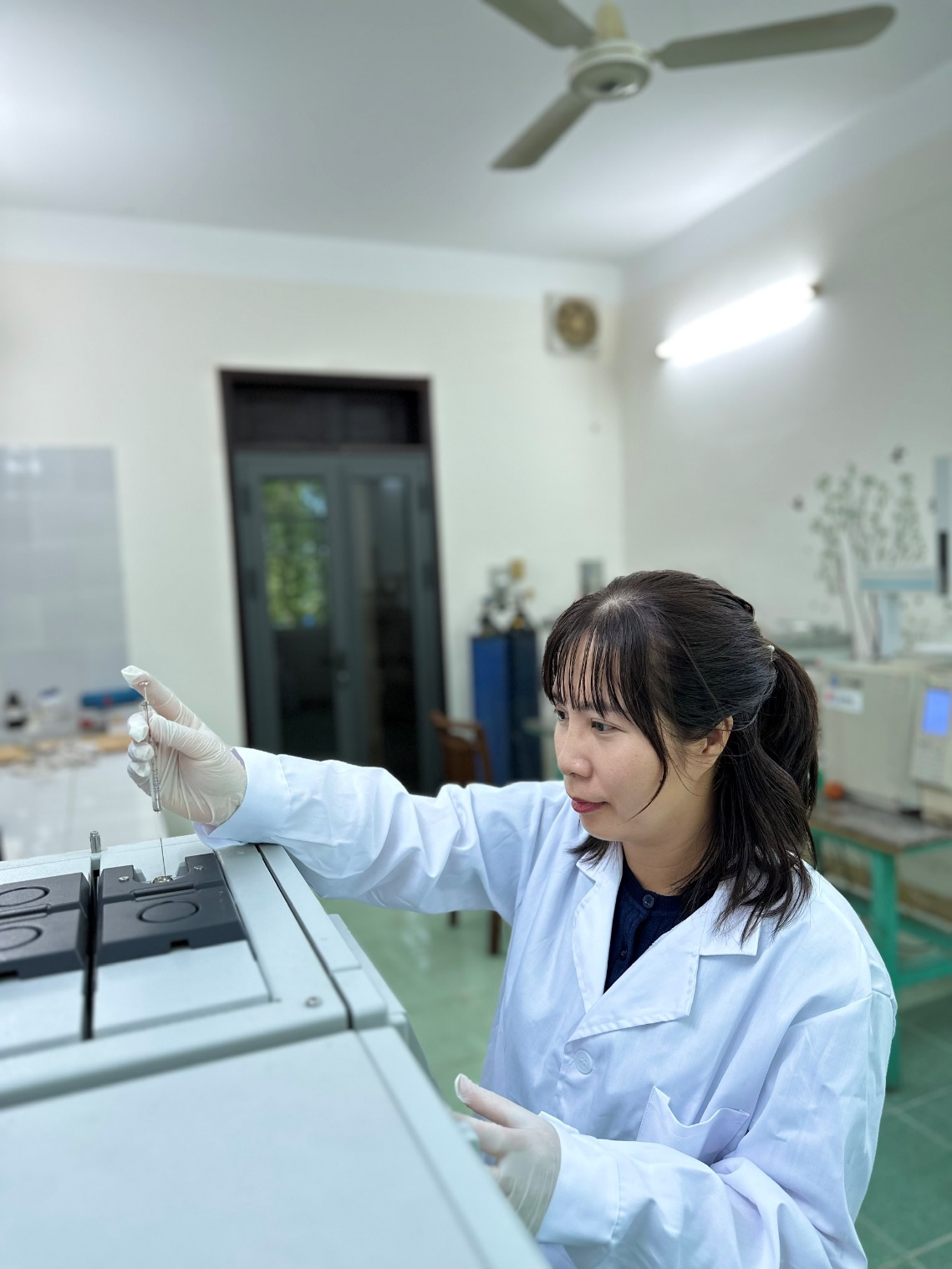

To overcome this limitation, M.Sc. Le Xuan Thanh Thao and her research team conducted the study titled “Development of a High-Performance Forward Osmosis Membrane for Heavy Metal Removal from Electroplating Wastewater” (Project Code: VAST07.02/23–24). The objective was to develop a next-generation FO membrane with enhanced permeability by integrating hydrophilic dextran, providing a cost-effective and sustainable solution for industrial wastewater treatment.

Membrane Structure Optimization – Enhancing Separation Efficiency

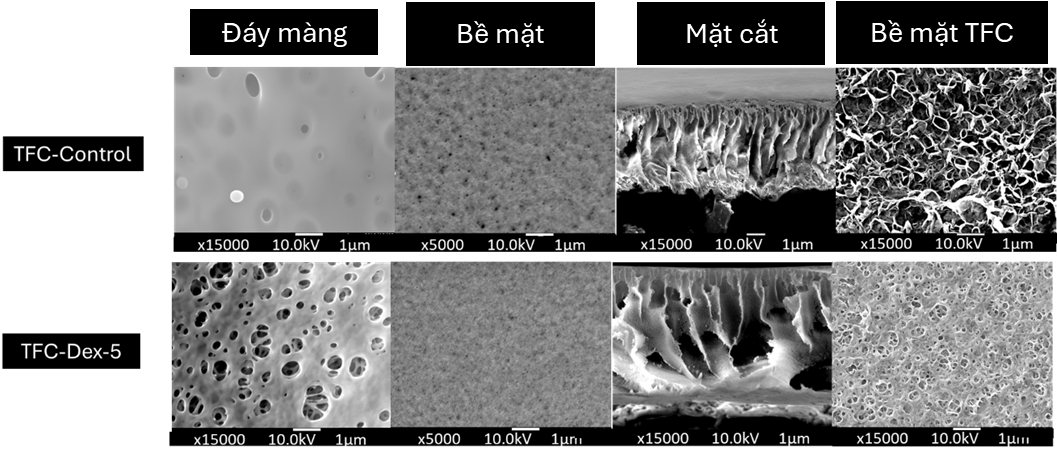

The study demonstrated that dextran, a natural hydrophilic polysaccharide, when incorporated into the polyethersulfone (PES) support layer, significantly improved membrane porosity and wettability. The water contact angle decreased, pore density increased, and the cross-sectional structure became more porous, as clearly observed under scanning electron microscopy (SEM).

These structural modifications effectively mitigated internal concentration polarization, one of the major bottlenecks in traditional FO systems that lowers the effective osmotic pressure and thus reduces water flux. The support layer containing 5% dextran achieved double the water flux compared to commercial thin-film composite (TFC) membranes under identical test conditions, while maintaining excellent salt and heavy metal ion rejection, exceeding 97% for metals such as As, Pb, and Ni.

The research team also conducted pilot simulations using synthetic electroplating wastewater to assess real-world applicability. According to M.Sc. Thao, the team thoroughly analyzed the influence of key parameters such as feed solution (FS) and draw solution (DS) osmotic pressures, pH, and concentration levels, clarifying the membrane’s performance mechanisms under variable field conditions.

Unlike many previous studies that focused mainly on membrane fabrication, this research emphasized the interrelationship between structure, property, and performance, offering a systematic and practical approach to water treatment applications. Compared with recent studies that use advanced nanomaterials (e.g., graphene oxide, zeolite), the use of dextran offers several advantages: biocompatibility, low cost, and technological suitability for small and medium-sized enterprises (SMEs) in Vietnam.

Achievements and Scientific Contribution

Based on experimental success, the team established a standardized fabrication protocol for high-performance FO membranes and produced ready-to-transfer prototypes. The results have been published in both international and national scientific journals, including two peer-reviewed papers demonstrating strong application potential:

-

The international article, published in Chemical Engineering Research and Design (SCIE, Q2), showed that dextran incorporation doubled the water flux compared to commercial TFC membranes while maintaining stable rejection performance.

-

The second publication, focusing on arsenic removal, demonstrated that the TFC-Dex membrane not only achieved near-complete removal of arsenic—a carcinogenic contaminant common in electroplating effluent and groundwater—but also addressed pressing environmental challenges in Vietnam.

According to M.Sc. Le Xuan Thanh Thao, the research was driven by a practical goal: developing a technically effective yet economically viable solution suited to Vietnam’s industrial context. She emphasized:

“We aim to create a membrane that performs efficiently not only in the laboratory but also at real industrial scales—where cost, stability, and operational simplicity are crucial factors.”

She further noted that selecting biopolymer materials such as dextran enhances membrane performance while ensuring environmental safety, scalability, and sustainability. “The key,” she added, “is to balance both technical excellence and economic feasibility. A technology that works only under ideal conditions will hardly reach practical deployment.”

Scientific and Practical Significance

Compared with conventional reverse osmosis (RO) systems, which require high energy input, the FO membrane technology developed in this study offers clear advantages in energy efficiency, process flexibility, and compatibility with hybrid FO–RO configurations. With near-complete heavy metal removal, robust structural integrity, and a simplified fabrication process, the new FO membrane is not only applicable for electroplating wastewater treatment but also adaptable for water reuse, industrial wastewater management, and pre-treatment for advanced filtration systems.

This research marks an important step forward in Vietnam’s environmental technology development, presenting a sustainable, low-cost, and scalable approach to industrial wastewater treatment aligned with global trends in green innovation and circular economy practices.

M.Sc. Lê Xuân Thanh Thảo, Researcher at the Institute of Science and Technology for Energy and Environment, Vietnam Academy of Science and Technology (VAST).

Source: Trung tâm Dữ liệu và Thông tin khoa học, Viện Hàn lâm Khoa học và Công nghệ Việt Nam.

- Sci-tech cooperation agreement signed between Institute of Science and Technology for Energy and Environment (ISTEE) and New Technology Application and Tourism Company Limited (NEWTATCO)

- SUCCESSFULLY ORGANIZED THE TABLE TENNIS TOURNAMENT “VAST SUPER CUP 2024”

- The Trade Union of the Institute of Science and Technology for Energy and Environment responded to “Ao Dai Week” in 2024 and organized Teambuilding to celebrate International Women’s Day

- Announcement of the Kurita Fund on Water and Environment for young researchers in 2024

- Talk Show: Green Business Transformation – From Challenges to Action