(Dân trí) – A talk show was held at the Dân trí newsroom at 9:00 a.m. on July 28, 2025, with the participation of Dr. Nguyễn Hoài Nam, Deputy Director of the Institute of Science and Technology for Energy and Environment (ISTEE) under the Vietnam Academy of Science and Technology (VAST).

In the context of growing requirements for greenhouse gas emission reduction and green transition, not only domestically but also in major export markets such as the European Union (EU), Vietnamese enterprises are facing significant challenges. However, this also presents an opportunity for businesses to pursue sustainable and efficient growth, aligning with global development trends.

The talk show titled “Green Transformation in Enterprises – From Challenges to Action” provided both businesses and readers with deeper insights into this transition process. The program featured Dr. Nguyễn Hoài Nam, Deputy Director of the Institute of Science and Technology for Energy and Environment (ISTEE), under the Vietnam Academy of Science and Technology (VAST).

Dr. Nguyễn Hoài Nam – Deputy Director of the Institute of Science and Technology for Energy and Environment (ISTEE) under the Vietnam Academy of Science and Technology (VAST) (right) – poses for a photo with Mr. Lê Đắc Thịnh Đồng, Chief of Administrative Office of Dân trí Newspaper (Photo: Hải Long).

The program is part of the Talk GreenBiz – Compass for Green Growth seminar series, initiated by the For a Green Future Foundation, aiming to raise awareness and strengthen the capacity for action among Vietnamese enterprises in response to the rapidly emerging carbon pricing mechanisms.

Dr. Nguyễn Hoài Nam shared valuable insights to help businesses pursue sustainable and efficient growth, aligning with global development trends (Photo: Hải Long).

The For a Green Future Foundation, established by Vingroup Group on July 7, 2023, carries the mission of contributing to the Government’s goal of achieving net-zero emissions by 2050.

List of questions and exchanges shared by Dr. Nguyễn Hoài Nam

By Hoàng Phổ

Question:

How does the pace of green transition among Vietnamese enterprises compare with other ASEAN countries? How should Vietnam design its emission reduction strategy to anticipate the requirements of export markets?

Dr. Nguyễn Hoài Nam:

In the research we conducted to prepare for today’s talk show with Dân trí Newspaper and the For a Green Future Foundation, we found that 70–80% of the data sources we accessed did not originate from Vietnam. This indicates that businesses in other ASEAN countries are performing better than us—or perhaps we are doing well but not communicating it effectively. I’d like to leave this as a point of reflection for readers—to draw their own insights from experience—but I remain hopeful that we are indeed making good progress.

As for how Vietnamese enterprises can meet export requirements, we can look at a familiar example in the textile and garment industry, which contributes significantly to GDP and exports while employing a large workforce. Vietnam’s textile sector is facing intense competition not only within ASEAN but also globally. In a world increasingly focused on reducing greenhouse gas emissions, enterprises engaged in manufacturing, finishing, and exporting textile products must adopt a practical and updated perspective—understanding where we stand and how to strengthen our capacity and competitiveness to keep pace with global sustainability demands.

In the field of green transition and ESG (Environmental, Social, and Governance), Vietnam’s textile and garment industry has been among the most systematic in its approach — from identifying sustainability issues and understanding its carbon footprint, to building concrete strategies for implementing green practices. The Vietnam Textile and Apparel Association (VITAS) has provided extensive guidance and support to help enterprises continuously improve operational efficiency, such as:

- Using recycled fuels — for instance, fabric scraps from cutting operations are co-fired with coal in boilers to reduce greenhouse gas emissions, or coal is completely replaced with more environmentally friendly biomass fuels;

- Upgrading production technologies, such as adjusting factory lighting intensity according to each production stage instead of installing uniform lighting throughout;

- Promoting inclusive development, by empowering female workers and electrifying employee transport systems.

Notably, as early as two years ago, some textile enterprises had already begun assisting workers in switching from gasoline to electric vehicles.

“These examples show that every industry has its own opportunities and solutions,” Dr. Nguyễn Hoài Nam emphasized. “As long as businesses act responsibly, align with social goals, and understand that green transformation not only benefits their operations but also enhances brand value, customer trust, and long-term competitiveness, they will gain both economic and reputational advantages.”

Question – Nguyễn Viết Trường:

Are there any solutions that allow enterprises to share the cost of clean technology adoption with suppliers or logistics partners?

Dr. Nguyễn Hoài Nam:

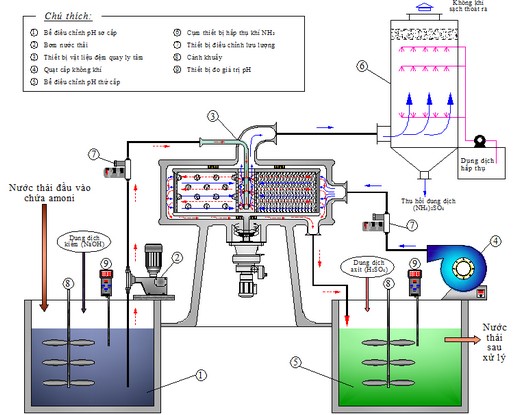

In several developed countries, there are already established mechanisms for this. For example, within the energy-saving and energy-efficiency markets, there exists the SCO model — referring to Service Companies for Energy (Energy Service Companies – ESCOs). These companies act as intermediaries that provide contractual energy efficiency solutions for businesses, often through performance-based contracts.

To illustrate, suppose a business operates a building that’s over 15 years old, equipped with outdated air conditioning systems (non-inverter) or inefficient lighting. An ESCO will conduct a comprehensive energy audit, identifying areas and systems where efficiency can be improved. The company then designs an investment plan, proposing technology upgrades along with a capital recovery schedule, and takes responsibility for the initial investment.

The enterprise then pays back the ESCO over time using a portion of the cost savings achieved from reduced energy consumption. This shared-benefit model helps businesses transition to cleaner, more efficient technologies without bearing all the upfront costs, while enabling service providers and suppliers to profit from performance improvements — a win–win model for sustainable development.

Dr. Nguyễn Hoài Nam:

Currently, Vietnam’s policies on energy saving and efficiency have also begun to include provisions to legalize and encourage the operation of energy service companies (ESCOs). This example illustrates that, in the process of green transformation, enterprises are not alone—there are always market partners ready to provide technical and financial support services to help them implement sustainable solutions.

Question – Phương Hoài:

An unsustainable supply chain can lead to higher indirect emissions. Where should businesses start when assessing and improving their supply chains?

Dr. Nguyễn Hoài Nam:

We see many opportunities for businesses to manage emissions across the full life cycle of their products—not only within their own factories but also throughout the distribution and consumption stages. For instance, in Australia, companies are no longer focusing solely on Scope 1 emissions (direct emissions from owned or controlled sources), but have expanded to include Scope 2 (indirect emissions from purchased electricity) and Scope 3 (emissions from their distributors and partners).

This process requires a clear roadmap, strategic investment, and enhanced technical capacity. My advice is that Vietnamese enterprises should first understand their Scope 1 emissions profile and then, over time, progressively manage Scope 2 and Scope 3 emissions, following the path already taken by developed economies.

Question – Trần Oanh:

Integrating new technologies into existing production systems often causes disruption. How should businesses prepare operationally and in terms of workforce training?

Dr. Nguyễn Hoài Nam:

This depends largely on which process or stage of the value chain a business wants to “green.” My recommendation is that before making any major transition, enterprises should consult with specialists or certified service providers in the field.

This advice applies not only to large corporations but also to small and medium-sized enterprises (SMEs). In Vietnam, technical consulting and energy efficiency services have become relatively accessible and affordable. The service fees are not prohibitively high, and businesses should make full use of them. After more than a decade of implementing the Law on Economical and Efficient Use of Energy, Vietnam has developed a solid base of qualified energy experts capable of auditing and identifying inefficient stages within a production process.

The consultation process can also be tailored to the financial capacity of each business. For instance, enterprises with limited budgets can opt for a Preliminary Energy Audit, which requires only a few days of on-site assessment but still provides practical recommendations for improving efficiency.

To illustrate, even for a single building, a few simple energy measurements can help determine which systems are consuming electricity inefficiently and which equipment should be replaced or optimized. Some companies have even achieved significant savings through non-investment solutions, such as process adjustments, decision-making improvements, and better energy management practices.

For larger-scale enterprises, technological interventions must be carefully evaluated. For example, if a production line has been in operation for 7–8 years, businesses should invite experts to coordinate with the original equipment manufacturers to determine which parts should be replaced and which can still operate efficiently. Balancing technology upgrades, production continuity, and capacity optimization always requires professional technical consultation to avoid unnecessary disruptions while ensuring long-term sustainability.

*********

MC:

Regarding green finance, could you share some guidance on how businesses should approach this — through intermediaries such as banks, investment funds, or development organizations?

Dr. Nguyễn Hoài Nam:

Green finance and climate finance are now global priorities, especially for developing countries — not only in Vietnam. At almost every session of the Conference of the Parties (COP) under the UN Framework Convention on Climate Change (UNFCCC), these topics remain central issues of discussion.

Fundamentally, enterprises themselves must be the driving force for their own green transformation — by reducing resource consumption, creating environmental value for communities, and cutting greenhouse gas (GHG) emissions. However, they also need access to technologies and financial resources to make these transitions feasible.

Currently, climate finance can come from various sources, including green-labeled loans disbursed through commercial banks. For example, between 2019 and 2021, HDBank launched credit packages supporting enterprises installing rooftop solar systems. These credit schemes created positive spillover effects, enabling businesses interested in renewable energy to collaborate with third-party solar investors, who in turn leveraged green credit financing to implement projects.

Another important source of funding comes from international development organizations, such as the French Development Agency (AFD), the World Bank (WB), the Korea International Cooperation Agency (KOICA), and the Danish Energy Agency (DEA). Over the years, these institutions have continued to cooperate with Vietnam’s ministries and agencies to implement green transition and sustainable energy programs that directly support Vietnamese enterprises in their path toward low-carbon and climate-resilient growth.

Dr. Nguyễn Hoài Nam:

If readers are enterprises in the industrial sector, they can easily access information on green financing and support mechanisms via the official portals of the Ministry of Industry and Trade (MOIT). The Ministry of Finance also operates several programs supporting corporate green transition. Beyond providing technical assistance, these initiatives also offer financial instruments.

For instance, the “Promotion of Energy Efficiency in Industry” project by the MOIT provides loan guarantee support for enterprises. Through partnerships with commercial banks such as SHB, businesses can access preferential loans with simplified appraisal procedures, enabling them to implement energy-saving measures like waste heat recovery systems in cement plants or kiln optimization in steel factories.

In addition to these mechanisms, green bonds are emerging as a major channel of green finance in the region. Within Southeast Asia, Singapore has successfully issued multiple green bond programs. As Vietnam aims to establish financial centers in Ho Chi Minh City and Da Nang, learning from Singapore’s experience could help domestic enterprises diversify their access to capital through sustainable finance instruments.

MC:

More specifically, regarding the voluntary carbon market, which types of businesses stand to benefit from participation?

Dr. Nguyễn Hoài Nam:

In this case, the buyers are those seeking environmental value through carbon credits. For them, acquiring credits demonstrates a measurable effort toward reducing greenhouse gas (GHG) emissions and achieving their ESG or compliance targets.

On the other hand, sellers—often companies implementing emission-reducing activities—can gain significant additional revenue streams from selling their verified credits. This not only improves their cash flow but also makes their balance sheets more favorable while encouraging continued investment in green projects.

MC:

What is your assessment of the potential of Vietnam’s voluntary carbon credit market? Do you see real opportunities for domestic businesses?

Dr. Nguyễn Hoài Nam:

The voluntary carbon market has both supply and demand sides. In Vietnam, most enterprises interested in carbon credits are currently acting as suppliers, generating credits through their emission reduction or offset projects.

The buyers, in contrast, are typically large international corporations, including many on the Fortune 500 or Forbes 500 lists, who purchase credits to meet compliance requirements or corporate ESG goals.

Vietnam plans to launch a domestic carbon market by 2028, under which the Government will allocate emission quotas to major emitters. When these entities exceed their assigned quotas, they will need to purchase additional credits—initially from domestic suppliers.

At present, voluntary carbon credit transactions are mostly bilateral, based on direct agreements between buyers and sellers, with limited government regulation. Vietnam has already engaged in international mechanisms such as the Kyoto Protocol and cross-border Clean Development Mechanism (CDM) projects related to CBAM (Carbon Border Adjustment Mechanism).

For now, there are no formal government adjustments or centralized frameworks for voluntary markets, so businesses should proactively seek credible intermediaries or brokers who can facilitate transactions and verification between sellers and buyers.

MC:

The first step in green transition is measuring greenhouse gas emissions, or more specifically, conducting a GHG inventory. From your perspective, what technologies should businesses explore when choosing tools for this process?

Dr. Nguyễn Hoài Nam:

In Vietnam, we already have a policy framework and regulatory roadmap for carbon management, with the domestic carbon market expected to be operational by 2028. It’s important to note that not all enterprises are required to perform GHG inventories.

Under current Vietnamese regulations, only large emitters must conduct annual GHG inventories and report to competent authorities every two years. Smaller enterprises are not yet obligated to perform mandatory inventories.

However, in developed economies and countries with strong environmental policies, even small and medium-sized enterprises (SMEs) are encouraged and incentivized to conduct voluntary GHG accounting. This not only prepares them for future compliance but also enhances their market credibility and access to international partners and financing opportunities.

Ultimately, carbon measurement and management should be seen not as a regulatory burden but as an investment in long-term competitiveness, particularly as global supply chains increasingly demand transparent and verifiable sustainability data.

For large enterprises, conducting a comprehensive GHG inventory requires specialized solutions, data analysis, and expert support, since industrial production and transport processes often involve complex emission sources. Therefore, in addition to using technological tools and inventory software, it is essential to have qualified professionals involved in the process. In Vietnam, there are already consulting firms that provide GHG accounting and carbon management services, helping businesses perform accurate inventories in line with international standards.

For small and medium-sized enterprises (SMEs), we recommend starting with free and open-access tools. In the United States and the European Union, there are publicly available online tools that allow businesses to perform self-assessments of their emissions, such as those provided by the U.S. Environmental Protection Agency (EPA) or corresponding environmental management agencies in the EU and Japan.

In Vietnam, several tools have already been localized or developed by domestic experts, making them adapted to local business contexts. Moreover, some large Vietnamese corporations—beyond their core manufacturing activities—also provide digital and automation services for GHG accounting at reasonable and accessible costs. In some cases, consulting companies specializing in energy efficiency, climate change, or mitigation technologies even offer free inventory tools to encourage broader participation among SMEs in the green transition.

MC:

What lessons can Vietnamese enterprises learn from successful green transition models in Thailand or Indonesia? Are there any domestic success stories that could serve as examples for others?

Dr.Nguyễn Hoài Nam

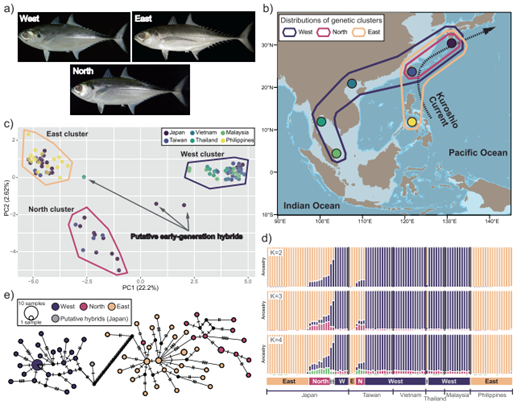

Based on comparative studies across the ASEAN region, I found an interesting pattern that helps indirectly contextualize the green transition landscape among Vietnamese enterprises. Data from Thailand and other ASEAN countries shows that, aside from Singapore, many economies that compete directly with Vietnam—such as Indonesia, Thailand, Malaysia, and the Philippines—have already advanced their green transformation at a relatively high level, particularly in traditional heavy industries like mining, cement, and steel.

However, these transitions often require significant capital and technical resources, meaning that progress tends to be led by large corporations. This situation mirrors Vietnam’s own context, where pioneering green enterprises are mostly large-scale companies, while small and medium-sized enterprises (SMEs) still show limited participation in the transition.

MC:

What are the key factors that enable leading enterprises—both in Vietnam and abroad—to succeed in their green transition journeys?

Dr. Nguyễn Hoài Nam:

For any enterprise, the internal motivation—the reason why it chooses to go green—is crucial. I believe the first factor that drives both leadership commitment and customer alignment toward green transformation lies in the tangible results it brings.

When a company embarks on a green transition, its leaders and stakeholders benefit from multiple dimensions:

- Improved product and service quality through cleaner production;

- Contribution to national and global GHG reduction goals;

- Reduced resource consumption; and

- Enhanced environmental and social impact, strengthening both brand reputation and market competitiveness.

However, through the projects we’ve participated in, we’ve identified two major barriers that businesses often face. First, determination and planning alone are not enough. Enterprises must understand how the transition will be carried out—which stages, which technologies, what level of investment, and which solutions are realistically accessible. Second, even after identifying suitable solutions, they must answer the question of where to find the resources—financial, technical, and human—to implement them.

These challenges underline the importance of interdisciplinary collaboration, public–private partnerships, and capacity-building initiatives, which together create an ecosystem that enables sustainable transformation rather than expecting businesses to act in isolation.

MC:

Could you elaborate on the technologies supporting emission accounting and carbon reporting, as well as the roles of green finance, voluntary carbon credits, and supporting ecosystems? What lessons can be drawn from pioneering enterprises?

Dr. Nguyễn Hoài Nam:

In my presentation titled “Corporate Green Transition – Opportunities and Challenges,” I will cover the following:

- Overview of Green Transition and GHG Reduction

- Geographical and Industrial Distribution

- GHG Mitigation Strategies

- Challenges and Barriers

- Case Studies of Leading Enterprises

- Conclusions and Policy Recommendations for Vietnam

Part 1: Overview

According to analyses by PwC and WWF, green transition contributes directly to economic growth. Economic development remains the top priority for all nations and organizations, but it must go hand-in-hand with social inclusion, equity, and poverty reduction.

While these goals focus on socioeconomic aspects, green transition adds an environmental dimension—specifically, ecosystem protection, biodiversity conservation, and climate adaptation for communities and organizations. The key mechanism to achieve these objectives is greenhouse gas (GHG) reduction.

Reducing GHG emissions is tightly linked to economic growth: it pushes us to develop low-emission growth models, use fewer natural resources, and strengthen systems and policies that support climate adaptation and mitigation at organizational, local, and national levels.

For enterprises, green transition refers to the process of adopting technologies and operational processes that lower emissions, improve energy efficiency, and enhance overall sustainability. When companies innovate their production lines and upgrade processes, they are not only reducing emissions but also improving competitiveness in their respective industries.

In Vietnam’s case, the proactive engagement of domestic enterprises in green transition aligns with the nation’s Nationally Determined Contributions (NDCs) submitted to the United Nations, and supports the commitment to achieving net-zero emissions by 2050.

Nevertheless, implementing these commitments entails specific responsibilities for businesses, especially in technological investment and innovation. Successful enterprises tend to combine modern technology, government incentives, and efficient management systems to achieve meaningful and measurable emission reductions.

Ultimately, green transition is not just about compliance—it is a strategic pathway to strengthen competitiveness, meet global sustainability standards, and attract green finance to ensure long-term growth.

Part 2: Geographic and Industrial Distribution

Across the ASEAN region, the most visible sectors undergoing green transition and GHG emission reduction include oil and gas, heavy industries such as cement, mining, and steel, as well as energy production. More recently, transportation and thermal power have also started implementing low-carbon initiatives.

Our research indicates that Vietnam is among the most active countries in advancing the green transition. Alongside Thailand and Indonesia, Vietnam has made notable contributions through its policies and corporate-level initiatives to reduce GHG emissions and enhance sustainability.

Part 3: Greenhouse Gas (GHG) Reduction Strategies

Enterprises have adopted various strategies to implement green transition measures within their operations. From a technological perspective, businesses must identify appropriate solutions based on their industry characteristics, production context, and product types.

In heavy industries, solutions such as waste heat recovery, optimization of filtration systems, and energy management systems have proven to be highly effective in reducing emissions. In addition, companies are actively seeking financial resources, leveraging green finance instruments such as green bonds and participating in government-led green public procurement programs to support their transition.

Part 4: Challenges and Barriers

Despite positive progress, several challenges remain for enterprises pursuing green transformation:

- Technological barriers: Identifying appropriate low-carbon technologies for each sector—cement, steel, electronics, and others—remains complex. Even researchers spend considerable time assessing which technologies are best suited to “green” specific industrial operations.

- High costs and production disruptions: Transitioning to new technologies often requires halting certain production lines or modules for retrofitting or replacement, affecting short-term productivity.

- Policy and regulatory gaps: Current policies are not yet fully synchronized. Some compliance requirements lack enforcement, reducing the motivation for businesses that have yet to adopt green practices.

- Supply chain limitations: Many enterprises lack the green supply chain capacity to support their transition. For example, suppliers may not yet be able to provide raw materials, components, or equipment that meet green standards, creating obstacles in accessing sustainable inputs.

- Non-technical constraints: Insufficient data systems, monitoring tools, and reporting frameworks for green transition reduce the overall effectiveness of GHG management and verification.

In summary, while Vietnam has demonstrated strong commitment and progress in green transformation, a systemic and multi-level approach—integrating policy reform, technological innovation, financial support, and capacity building—is essential to sustain momentum and expand participation beyond large enterprises to include SMEs across all sectors.

Part 5: Exemplary Applications of Technology and Innovation in ASEAN

Key examples across ASEAN highlight how technological innovation has played a pivotal role in advancing industrial decarbonization. In Thailand, waste heat recovery (WHR) technologies have been successfully integrated into the cement sector. In Indonesia, optimization of membrane filtration systems and energy management frameworks in manufacturing plants have yielded significant reductions in greenhouse gas (GHG) emissions. Moreover, the adoption of alternative fuels—such as clinker substitutes in cement production—has helped curb fossil fuel dependence while improving process efficiency.

One notable case is the PTT Group, Thailand’s national oil and gas corporation—one of the country’s largest GHG emitters. Balancing international emission reduction commitments with domestic energy and production demands, PTT has deployed carbon capture, utilization, and storage (CCUS) technologies alongside automated emission monitoring systems to mitigate direct (Scope 1) emissions from extraction and refining operations.

In parallel, the corporation has implemented large-scale reforestation and ecological restoration initiatives to offset residual emissions, enhancing natural carbon sequestration capacities. PTT has also pursued digital automation, energy-efficient equipment upgrades, and adoption of international energy management standards, which collectively have improved operational efficiency across its production network.

In Vietnam, similar trends are emerging, with medium and large enterprises applying digital twin models—virtual replicas of production systems—to simulate and optimize operations before making real-world investments. This enables precise evaluation of inefficiencies and testing of process improvements or technological upgrades within a virtual environment.

As a result of these integrated approaches, the Thai oil and gas conglomerate has achieved a 25% reduction in GHG intensity compared to 2012 levels and aims to reach net-zero emissions by 2050.

Another significant case study is Thailand’s cement industry, one of the largest GHG emitters in the country. Leading firms in this sector have implemented waste heat recovery systems, alternative fuels, and clinker substitution to reduce energy consumption and carbon output. These initiatives are expected to cut emissions by approximately 2 million tons of CO₂ by 2030.

Collectively, these cases reveal that success in green transformation requires integrated strategies—combining multiple technologies, green financing mechanisms, government policy support, and carbon offset measures. Common traits among these successful enterprises include strong investment in advanced technologies, process innovation, and a clear long-term sustainability vision.

For small and medium-sized enterprises (SMEs), green transition does not always necessitate large upfront investments. Effective starting points include process optimization, improved resource management, and incremental operational improvements within existing systems.

Nevertheless, challenges persist—chiefly capital costs, technical barriers (e.g., limited access to comprehensive technology providers), and policy constraints (e.g., fragmented supply chain support and complex access to green finance). Addressing these issues remains critical for scaling green transformation across ASEAN industries.

Part 6: Conclusions and Recommendations

The green transition generates dual benefits—for both business performance and the environment.

From a business perspective, enterprises that successfully implement emission reduction and sustainability measures experience:

- Higher production efficiency and labor productivity,

- Lower operating costs,

- Enhanced brand reputation and market positioning, and

- Reduced regulatory and compliance risks, facilitating greater international market access.

In parallel, green transition inherently drives technological innovation, leading to improved profitability through cost savings in energy and materials.

From an environmental standpoint, corporate decarbonization directly contributes to national climate targets and pollution reduction. Technologies such as waste heat recovery, alternative fuels, and reforestation not only reduce CO₂ emissions but also enhance air quality, restore biodiversity, and revitalize ecosystems.

Overall, ASEAN’s collective efforts toward green transition—supported by green bond markets, sustainable public procurement policies, and financial incentives—have delivered measurable progress, reducing millions of tons of CO₂-equivalent annually.

To accelerate this trajectory, Vietnam and its ASEAN peers must continue to strengthen policy clarity, access to green investment resources, and institutional coordination. By doing so, businesses will not only transition more efficiently but also sustain long-term competitiveness in the global low-carbon economy.

Disclaimer:

The content presented and discussed reflects the personal views of the author and does not necessarily represent the official position of the Institute of Science and Technology for Energy and Environment (ISTEE) or the Vietnam Academy of Science and Technology (VAST).

Edited by: Bùi Mạnh Tường, Institute of Science and Technology for Energy and Environment (ISTEE)

Source: “Corporate Green Transition – From Challenges to Action,” Dân trí News

- The Faculty of Environmental Technology evaluated sectional reports and doctoral dissertation overview of PhD student Nguyen Duy Thanh

- The Trade Union of the Institute of Science and Technology for Energy and Environment responded to “Ao Dai Week” in 2024 and organized Teambuilding to celebrate International Women’s Day

- The Institute of Science and Technology for Energy and Environment and the Quang Ninh Department of Science and Technology sign a cooperation program for the 2025–2030 period.

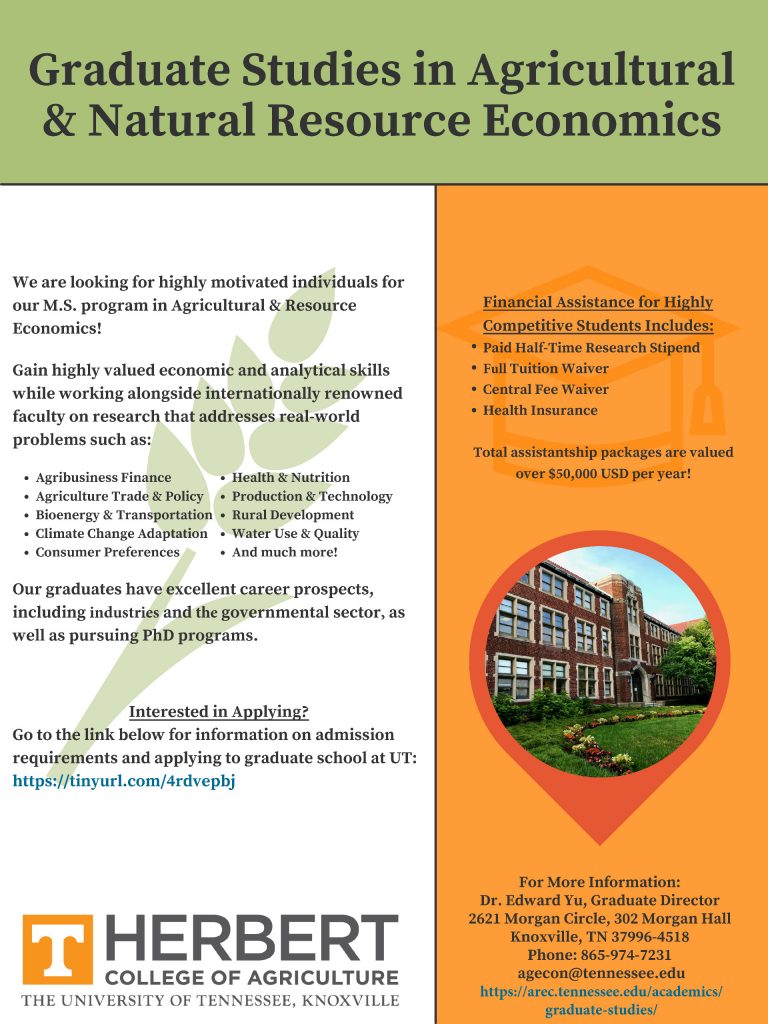

- Graduate Studies in Agricultural & Natural Resource Economics

- Sci-tech cooperation agreement signed between Institute of Science and Technology for Energy and Environment (ISTEE) and New Technology Application and Tourism Company Limited (NEWTATCO)